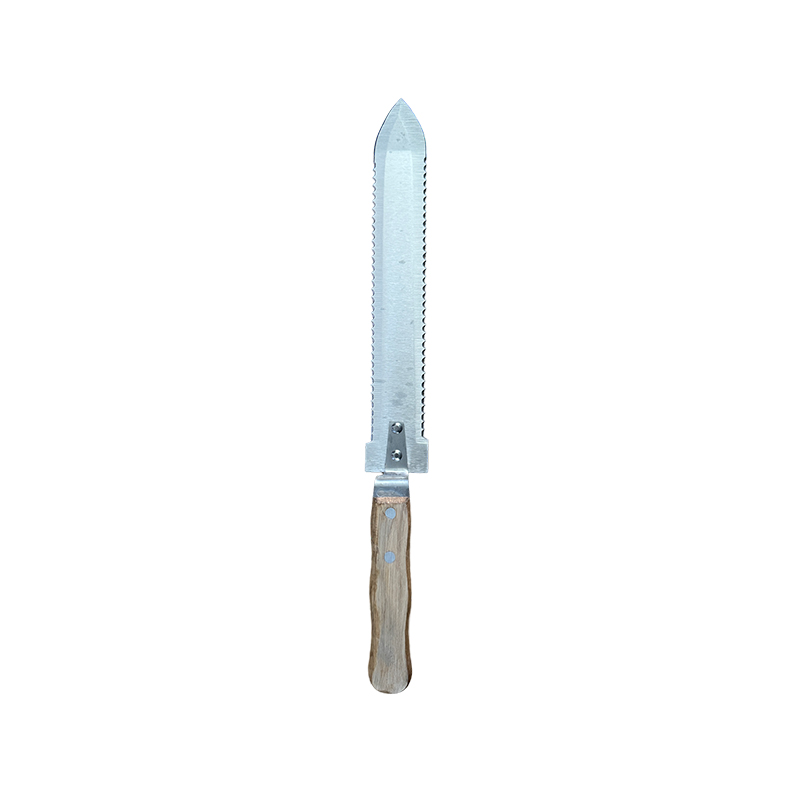

Honey Cutting Knife

GMD-1

GMD-2

GMD-3

GMD-4

GMD-5

GMD-6

GMD-7

GMD-8

GMD-9

1. Product Features

High-quality materials:

Usually food-grade stainless steel (304 or 201 stainless steel) is used to ensure corrosion resistance, wear resistance, safe and hygienic use.

The blade is precisely polished to maintain high sharpness, smooth edges without burrs, and ensure safe operation.

Precision technology:

Laser cutting or CNC stamping technology is used to ensure accurate product size and consistent shape.

The blade edge is chamfered to reduce the risk of accidental injury and extend service life.

Ergonomic design:

The handle design is ergonomic, and it can maintain a comfortable grip even after long-term use, reducing operating fatigue.

Efficient cutting:

Different tooth designs meet various honey cutting needs, ensuring that honey can be cut quickly and accurately during the honey cutting process, while maintaining the integrity of the hive and reducing interference with bees.

2. Application scenarios

Honey extraction:

Needle-type and single-tooth sharp knives are suitable for delicate operations, and finely cut honey combs in the hive.

Double-tooth and double-sided tooth honey cutting knives are suitable for large-scale honey cutting or hive disassembly, and can efficiently complete cutting tasks.

Honeycomb cleaning:

The honey cutter can also be used to clean excess beeswax and impurities in the honeycomb, which is convenient for subsequent honeycomb maintenance and honey extraction.

3. Customization and service

Customization options:

The blade length, width, tooth shape and handle design can be customized according to customer needs.

Support customized engraving of LOGO or product number to meet brand promotion and personalization needs.

Service advantages:

Provide OEM/ODM services to ensure that product quality is highly consistent with customer requirements.

Complete after-sales service system, provide technical support and product maintenance suggestions to ensure long-term use effect.